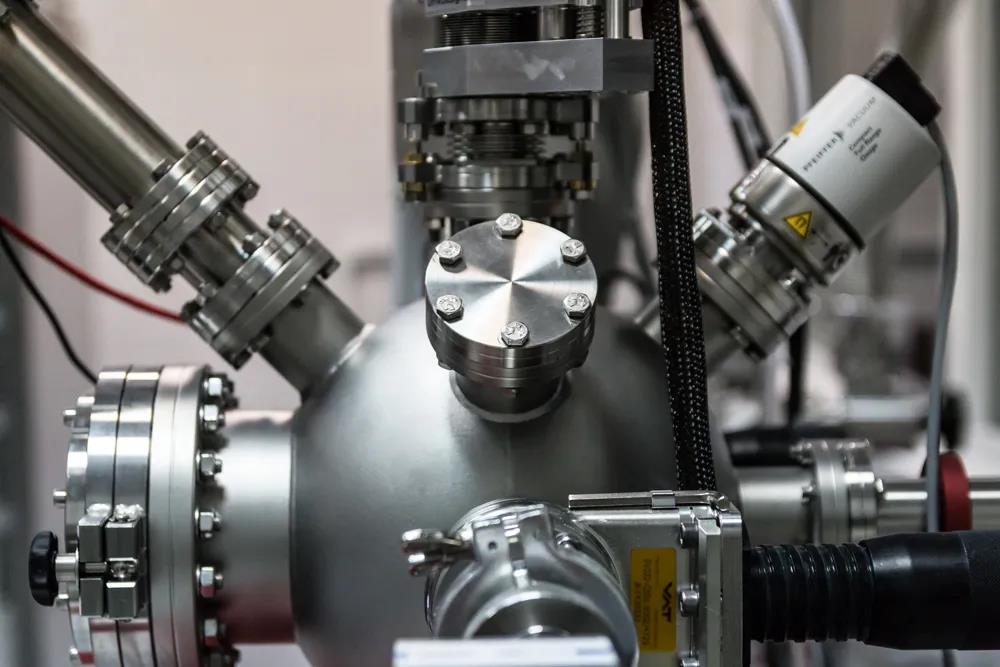

Equipment condition monitoring

In industrial production, the first thing we think of is a large number of machines and production lines. To make these machines produce together and create benefits, the work involved is far more than simple installation and equipment debugging. Especially in the process of using key equipment, the on-line monitoring of equipment performance and oil state is very important. If no appropriate monitoring system is deployed, it is very likely to miss the signs that a major catastrophic accident is about to happen. In industrial production, whether it is light industry such as food and beverage production, papermaking, or heavy industry such as steel smelting, oil and gas, any downtime caused by equipment failure may lead to a loss of millions or even tens of thousands of yuan. Therefore, the condition monitoring in industrial production is essential and a key work.

Data design of condition monitoring

The standby operation state is clearer

Condition monitoring is a system used to better understand the current operation status and performance of the equipment. By measuring the performance indicators of the equipment, it can ensure that the whole set of equipment can operate effectively and avoid failure. Different equipment, condition monitoring system measurement index is also different. For the common rotating machinery in industrial production, the conventional condition monitoring includes vibration monitoring. In other cases, the lubrication condition of the key components of the equipment is monitored. Through the measurement of these parameters, the maintenance engineer or equipment manager can understand the health status of the equipment. In short, condition monitoring is to measure the key indicators in the process of equipment operation and monitor its operation status. In the process of condition monitoring, a large number of data sets will be generated, which are very important for us to understand the operation of each component of the equipment. However, as far as it is concerned, these data alone are not enough. The data obtained from measurement must be transformed into executable measures to provide the basis for important decisions and equipment maintenance strategies

The development of artificial intelligence promotes the progress of condition monitoring technology

When the condition monitoring system is deployed, the whole process of industrial production will benefit. In fact, it is impossible to imagine a mechanical system that can operate efficiently without deploying a condition monitoring system. The better the condition monitoring system is deployed, the higher the efficiency of industrial production, which has been widely confirmed in the production practice of developed countries.

Benefits of online condition monitoring

⊙Know your equipment: even the equipment made by the same manufacturer will show different performance after it is put into production. By continuously monitoring the operation status of the equipment, the maintenance engineer or equipment manager will have a better understanding of the equipment and its components, which will be conducive to the leadership to make more predictive decisions.

⊙Catch subtle changes as early as possible: slight changes in the conductivity of lubricating oil during the operation of a certain set of equipment components may be an important signal indicating wear. By finding these small changes, we can have a clearer understanding of the operation mode of the equipment and help us more accurately predict the potential problems.

⊙Create an intelligent analysis model: after the deployment of the condition monitoring system, you can collect data about the equipment. More and more data can help to establish a model for the prediction and analysis of the equipment status, which are conducive to leaders to make correct decisions.

⊙Prevention of catastrophic failure: in case of equipment failure in the process of industrial production, it is not only a headache, but also a disaster. Especially for the production of critical equipment, we must at all costs to avoid downtime. Condition monitoring system can ensure that problems are found and handled before they get out of control, which means reducing the scale of loss.

To sum up, the deployment of an online condition monitoring system can be said to be an important asset investment. For this reason, you really need to spend some time thinking about how to improve the operation of related equipment.

It is the general trend to improve and upgrade the condition monitoring technology

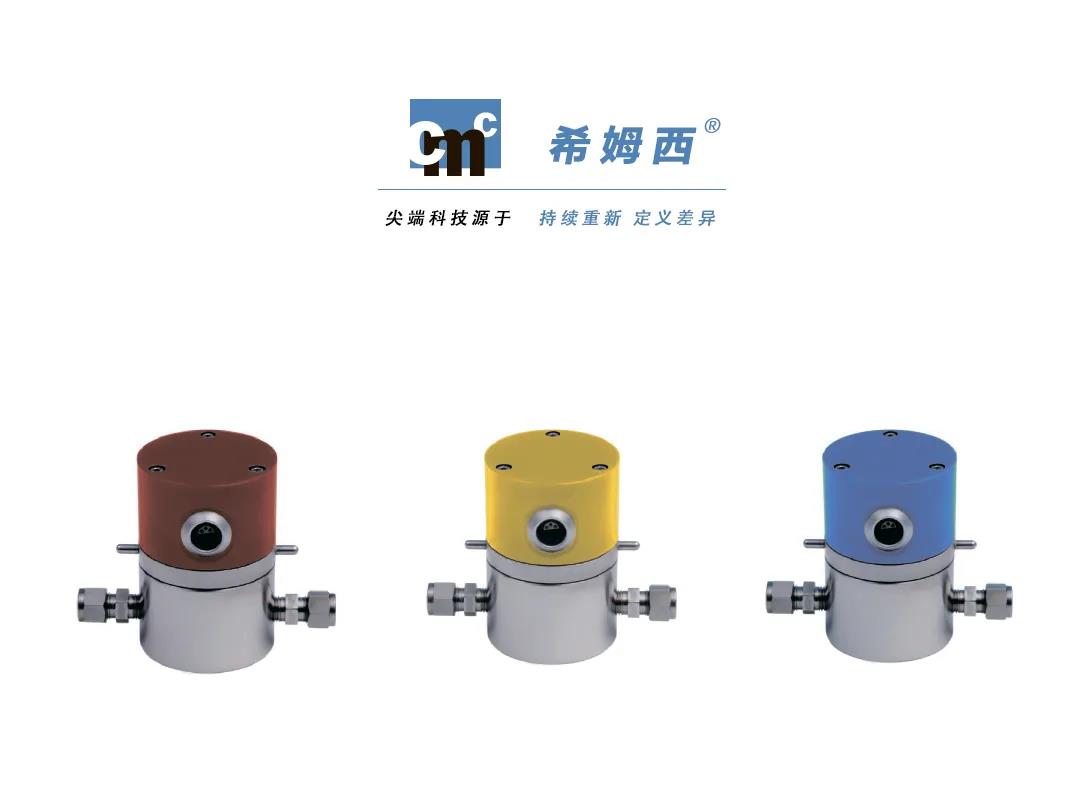

Our CMC product technology platform enables you to use the achievements of modern technology to quickly deploy. Whether it is to continuously monitor the important parts of oil lubrication of key equipment, or to systematically manage all relevant core important equipment, the progress of technology makes the condition monitoring more accurate and easier to deploy than ever before. Through the online monitoring system of equipment oil state, enterprise leaders can better understand the operation status of equipment, and make more intelligent decisions accordingly. We can help you better understand how to optimize the use of mechanical equipment, and take safety measures to avoid catastrophic equipment failure. With high sensitivity and professional sensors, customers can access the monitoring data anytime and anywhere to improve the reliability and efficiency of the equipment. If you are interested in upgrading the condition monitoring system, you are welcome to contact our team. We will share with you more unique solutions for CMC oil condition online monitoring.

About CMC (simsey)